Today’s data-centres and large offices are much reliant on fiber-optic cabling networks to transfer large packets of the data packets. Fiber-optic lines are thin flexible transparent strands of optically pure silica glass or plastic used to transport digital data via a light source. These strands are typically smaller in diameter than a human hair.

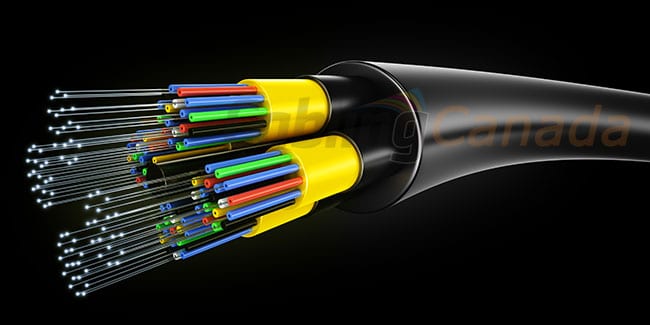

A Fiber-optic strand consists of multiple layers. The actual conductor is a silica glass or plastic core. This core is surrounded by a refractive coating called cladding which provides a reflective surface and causes the light to travel along the entire length of the core. The third layer is a buffer coding to protect against moisture and other damage. It also prevents light from escaping the strand and may have a colour coding for identification purposes.

Fiber-optic strands are typically bundled into a cable. These strands can be grouped as either tight or loose buffering cables. Both types of cables contain some type strengthening member such as an Aramid Yarn, stainless steel wire strands or gel-filled sleeves. They are however designed for different environments. A tight buffered cable consists of one or more bundled fibers strands covered by an outer jacket Often the outer jacket contains multiple layers to add structure to the cable and provide water resistance… In loose Buffer, the fiber strands are contained within buffer it is allowing the strands to move freely while also providing additional protection for the strands. The addition of buffered tubes and other protective layer causes the cable diameter to the larger any cables to be less flexible. It also means that tight buffer cables are more easily damaged than loose buffer cables. These factors make tight buffer cables more appropriate for indoor years and loose buffer cables primarily for outdoor use. Fiber Cable that that is used outdoor it is normally filled with a waterproof gel. The buffer tubes may also contain this gel as well as a water blocking coating between the inner and outer jackets. Both inner and outer jackets are made of materials designed to resist corrosion and add greater protection to the cable. Some cables also have a metallic arm accounting for strength and to protect against rodents. Fiber specifications list the core and cladding diameter as a ratio. Multimode fighter is usually either a 62.5 x 125 µm or 50 x 125 µm. Single mode fighter is commonly 9 x 125 µm. Fiber-optic cables have many advantages over copper cable including immunity to electromagnetic interference and radio wave interference. They are smaller and lighter than copper. Capable of greater transmission distance and higher bandwidth and have less signal degradation. the greatest it damages their ability to carry digital information over long distances at significantly higher rates than copper. For example fiber-optic cable may reliably transmit data up to 10,000 m compared to a few hundred meters for copper. This means that fewer cables are needed. Fewer signal repeaters are required. Less power is required and less maintenance is needed. fiber-optic cables also are considerably smaller in diameter than copper cable making them lighter to work with these attributes combined with increased resistance to lightning strikes make fiber-optic cabling ideal for data transmission. For all types of Network Cabling Services, please contact Cabling Canada.